Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

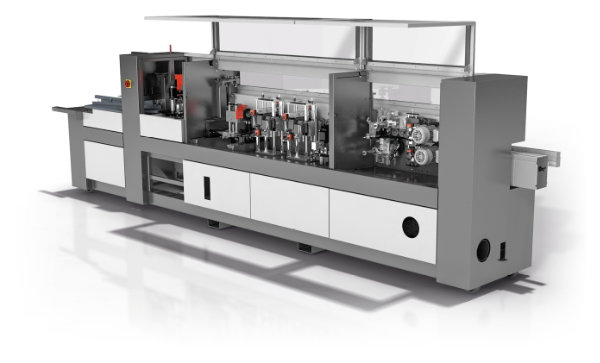

Macmazza TS90 Beamsaw

Macmazza TS90 Beamsaw

Macmazza has been Manufacturing Beam saws for 45 years, producing Special systems "turnkey" custom builds, along with standard machines such as the TS90 and refurbished saws. Control of the machines has been by PC since 1989, to guarantee the highest levels of technology on the market only the best component parts are used The Macmazza saws are easy to use and maintain, with amazing results in quality and production.

Our standard TS 90 that cuts 4300 mm covers a space of 5860 mm, that is the same longitudinal space as our competitors’ who cut 3200 mm!! The larger cutting length of the machine is very useful for the operator, making it easier to handle panels, the axis on the machine also have optimization, for cutting the exact measuremenys and to speed up processing. The operator can also finish the transversal cuts and, at the same time, other panels are loaded without stopping the cycle, parts of panels to recycle to improve the cut optimization can be parked and rotated 5 times (5 cut levels) more easily by just one operator on larger andlonger front tables without unloading and reloading them. It is possible to do pre (head) - cuts of 2 near packages at the same time, so it means more productivity, less manpower and less reject/waste!

NOTE: The space saving design allows minimum size inside your factory, thanks to :

1. Saw carriage being installed inside the base so halve its encumbrance in width2. Safety guards directly installed over 1./ under the beams, without increasing the space needed

(Saw body total length less than 6 meters, so can to be transported in a 20 “ container if required).

The Saw Carriage running inside the Panel Saw is composed of a main blade and a scoring blade to avoid the chipping in the lower part of the bottom panel.

Both cutting blades are raised and lowered by means of an electro-pneumatic system that allows the return pass under the working table once the cut is completed.

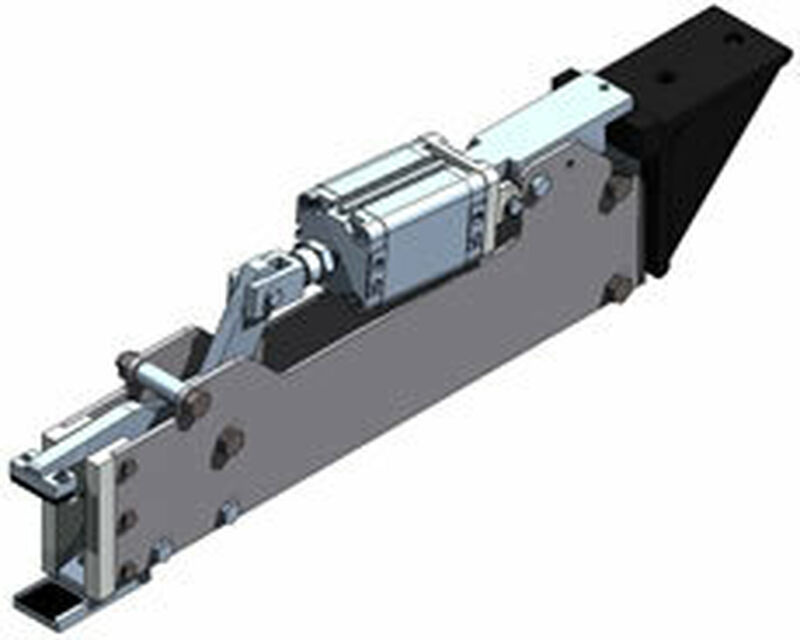

The Pusher/Positioner is made of a machined carriage running on two beams, with precision rack and encoder/ brushless motor.

The traction system is ensured by Rack and pinion and the transmission is made by turning shafts assuring a parallel and linear sliding of the structure.

The side aligning device on the cross cutting line (automatically activated and sliding on a rectilinear guide) is constituted by a carriage holding a roller, to which a pneumatic piston is connected, with adjustable and constant pressure.