Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

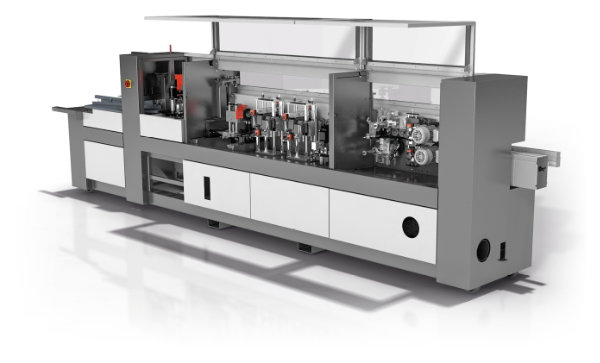

Introducing TigerStop

The automatic programmable stop and push feed systemTigerStop is an automated material pusher and stop that will turn your existing machine into a lean manufacturing asset. Take your operations to a whole new level with the product that started it all. It is easy and quick to mount on machines in the wood, PVC, aluminium and metal industry.

Tigerstop systems can be mounted left or right side of machine / equipment. The aluminium fence is robust and 100mm x 100mm in size. The power supply required is a standard 230v, 13amp 3 pin socket. Positioning speed of the Tigerstop is 60m per minute, and the repeat accuracy is 0.1mm. Information can be input via the 4 line LCD screen and key pad controller or by downloading to the controller. The maximum pushing weight is 100kg.

TigerStop Base Specification

Tigerstop can be fitted to existing tables as long as suitable brackets are available to help mount the Tigerstop, or tables can purchased specifically designed to take the Tigerstop.

-

Attach to your new or old machinery

-

Available in lengths of 2m, 3m, 4m, 4.8m, 6m, 6.8m, 7.4m, 8.5m, 9.2m and 9.6m

-

Best in class material optimization with Dynamic Optimization software upgrade

-

Push feed up to 80 kg with roller tables

-

TigerLink 6 Cut List Downloading software upgrade

-

Touch screen control

-

Push, pull, and position material

Measuring and adjusting is now a lot easier!

Accurately measuring material and subsequently setting manual length stops requires time and experience. Setting errors are not uncommon and they result in a loss of time and material. With the TigerStop this is a thing of the past.

Work faster

With the TigerStop you increase productivity. The automatic system allows a much faster processing of your long or heavy material. You key in the size or saw list and the TigerStop automatically moves to the correct position and performs the operation.

Higher precision

The TigerStop positions quickly to the desired length with repeat accuracy of +/- 0.1 mm, every time. Thanks to this precision, less post- processing is required and your tape measure or manual stop are unnecessary!

Easy to use

The TigerStop is particularly user-friendly. The simple operation speaks for itself, so you can get started quickly. Where you used to determine the length with a manual stop or tape measure, the TigerStop now does this very simply and quickly.

It is no longer necessary to adjust the machine, which saves you money.

The TigerStop has a large number of standard functionalities and is easy to mount on existing machines used in the wood, aluminium, metal and plastic industries.

Do you work with heavy or very long materials?The HeavyDuty is the heavy version of the TigerStop and offers a load capacity of no less than 600 kg and 24 meters! Just like the TigerStop, it enables fast and accurate positioning time and time again.

As the UK's TigerStop Dealer, R&J Machinery is pleased to present a selection of exclusive benefits that no other UK supplier can provide. To discuss TigerStop exclusives, please call our office team on 01455 840224.

Expert Commissioning

Configure your TigerStop for optimal performanceIt doesn't end with your purchase. We want you to get maximum performance from your new TigerStop panel saw from day one, and continuing long into the future. To ensure that your machine is installed, commissioned and operated to its full potential, our customers are given exclusive access to a range of commissioning videos that are presented by our expert engineers, and professionally produced. The videos cover the topics most important in the successful setup and operation of TigerStop machines, and offers an unmatched guide to safe-guarding your machinery investment for many years to come.

Machines In Stock

All configurations in-stock for fast despatchAs the UK Agent for TigerStop, R&J Machinery has been able to get ahead of Brexit-related delivery delays to secure an impressive inventory of all of the main configurations of machine from across the TigerStop automatic push stop range.

These machines are available on-site for in-person demonstrations (compliant with current lockdown rules) and for fast despatch to customers across the UK. Call our experts on 01455 840224 to secure your TigerStop today.

TigerStop Servicing

Woodworking machines are only as good as their preparation. Our in-house team of trained engineers are on-hand to visit your workshop and provide you with scheduled TigerStop servicing, ensuring that your machines are optimised for maximum performance and continue to meet safety standards.

TigerStop... Fast and accurate... every time

TigerStop was founded in a garage in 1994 by an ambitious husband and wife duo who wanted to help manufacturers like themselves reduce waste, measure material more accurately, and ultimately produce higher quality goods more efficiently.

TigerStop has since become a global leader in automated stop/gauge and pusher systems under the TigerStop and SawGear brand names. Headquartered in Washington State, TigerStop is a U.S. manufacturer with a second manufacturing and distribution facility in Europe, a distribution network spanning six continents, and product support in five languages.

R&J Machinery is proud to be the UK Agent for TigerStop

R&J Machinery has a long relationship with TigerStop dating back over 20 years, and we are proud to be the Main UK Agent and Sole UK Importer for their machines and spares. We are one of the top-tier suppliers of TigerStop products across all of Europe, and our team of service and repair engineers travels to TigerStop EU in Holland annually for training on the latest machinery developments.

You can be sure that our team are fully qualified to offer you guidance on the ideal TigerStop setup for your workshop, and are fully qualified to service and maintain your existing machines to the highest standard. We look forward to talking to you soon about all things TigerStop!

For sales, servicing, parts, advice and support, please call our office team on 01455 840224.

Like the TigerStop? Book a Demo!

Test-drive our machinery in our 16,000 sq ft facilityOur machines are ready for your inspection and testing at short notice in a purpose-built environment. Why not visit us at our location in Leicestershire to compare and contrast similar machines, and have our experts show you the key differences between models and brands?

Request TigerStop Servicing Information

R&J Machinery's in-house team of trained engineers are on-hand to visit your workshop and provide you with scheduled TigerStop servicing. To request more information about the servicing packages we offer, please speak to our knowledgeable team on 01455 840224 or complete this enquiry form.