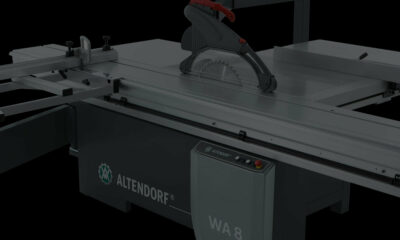

Altendorf WA8 TE

Solid build quality with flexibility and performance you can count on

Introducing the Altendorf WA8 TE

Available from only £72.09 per week on our competitive finance packages.

A high-performance panel saw that you can count on

Looking for a robust panel saw that is ready for the any task and easy to operate? Look no further than the Altendorf WA8. Whether you’re squaring panels or cutting complex angles and mitres, the Altendorf WA8 is the right companion for you. Manufactured to Altendorf’s rigorous technological standards, the WA8 stands-out with a solid build quality and ergonomic flexibility. This sliding table is typically Altendorf – smooth running, accurate and incredibly reliable.

Downloads

The Altendorf WA8 TE: Performance you can count on

R&J Machinery is proud to present the Altendorf WA8, a robust sliding table saw available in stock in TE and X models to the UK market. Whether you're squaring panels or cutting complex angles and mitres, the Altendorf WA8 panel saw is a capable companion for you.

The Altendorf WA8 TE with motorised rise/fall and tilt adjustment of the main saw blade – offering simple and accurate adjustment at the touch of a button. The digital display of the angle remains in your field of vision at all times during the cutting operation.

| Motorised Rise & Fall and Tilt Adjustment Motorised rise/fall and tilt adjustment of the main saw blade |

|

Sliding Table

The Altendorf sliding table is renowned for its smooth and exact running. This is hallmark of an Altendorf, and it all comes down to design: the table runs on large dumb bell rollers sandwiched between hard chromed guide bars, guaranteeing absolute precision. The system's large rollers ensure smooth action, meaning the table takes less effort to move and glides as securely as if it were on rails. This quality running will endure decades of heavy load bearing in the constant presence of dust and chips, and it needs virtually no maintenance. Each time the table moves, the brush fitted to the upper part automatically cleans the round guide bars. The system operates without any lubrication. The table’s hollow multi-chamber aluminium extrusion guarantees optimal torsion resistance and rigidity.

|

|

Rip Fence

The rip fence is smooth and precise to adjust. The hard chromeplated round bar ensures the fence moves smoothly. If you need to divide large panels, you can swing the rip fence away under the level of the machine table.

|

|

Crosscut Fence

The robustly mounted crosscut fence enables precise cutting of 90° angles. All settings are easy to read off the slanted scales. The flip stops are robust, free of play and are easy to slide individually along the full crosscutting range.

|

| Motor Rating Motor rating 5.5 kW (7.5 HP), with three speeds (3,000, 4,000 and 5,000 rpm), manually adjusted. |

| Cutting Height Cutting height 125 mm max. |

|

Large Extraction Hood

The large Altendorf extraction and safety hood system boasts a design which ensures optimised airflow. You can switch between narrow and wide hoods in seconds. The hood allows cutting heights of up to 125 mm (with or without scoring unit) and can be swung away fully to one side.

|

|

Machine Frame

The WA8 has a torsion-resistant machine frame built in the same way as the machine frames for the F45 series. The frame design ensures very smooth running and stability. The machine frame is fully enclosed.

|

|

Machine Frame Control Panel

All functions are easily accessed on the control panel on the machine frame. You can control the rise/fall and tilt of the main saw blade at the touch of a button. The tilt angle is shown on the digital display.

|

|

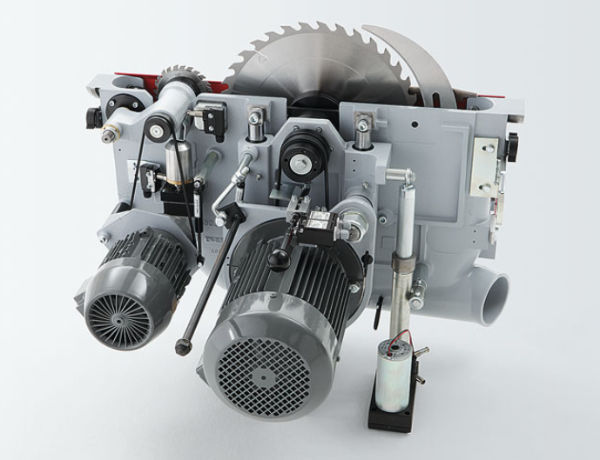

Saw Unit

The Altendorf saw unit is the engineering heart of all our saws. It is a powerhouse produced with the latest manufacturing technology. The saw shaft runs incredibly smoothly: this is because it is electronically balanced as a fully assembled unit, and extensive use is made of cast components. The high-precision vertical movement of the unit is linear with maintenance-free guide bearings. The robust tilt quadrants incorporate the traditional Altendorf tongue and groove connection system, which allows the whole unit to tilt easily and precisely to exactly the correct angle.

|

|

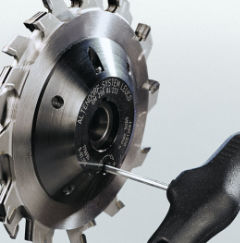

Scoring Unit with Motorised Adjustment

The scorer prevents chipping out on the underside of laminated panels. The rise and fall is motorised, the lateral adjustment manual. When the scoring blade is switched on, the scorer moves to the height stored. When either the main or scoring blade is switched off, the scorer moves back under the table. The scorer has an independent 0.75 kW (1 HP) motor and turns at 8,200 rpm.

|

Altendorf Servicing

Woodworking machines are only as good as their preparation. Our in-house team of trained engineers are on-hand to visit your workshop and provide you with scheduled Altendorf servicing, ensuring that your machines are optimised for maximum performance and continue to meet safety standards.

Altendorf Spares

Altendorf Manuals

With a long history of partnership with Altendorf, we have amassed an extensive collection of manuals for almost all Altendorf's that have ever been built. We are happy to provide these documents to you at no cost!

Precision machinery since 1906

Altendorf are responsible for the introduction of the first sliding table panel saws. Designed by Wilhiem Altendorf in Berlin back in 1906, Altendorf panel saws were used for his own production of furniture.

Today, Altendorf employs over 260 people, has factories in Germany, China, and Brazil and sells over 2,600 sliding table saws per year into the wood, metal and plastic industries. As a company it is renowned as a specialist manufacturer of sliding table saws with a patented table mechanism, meaning that Altendorf panel saws are still the most desired woodworking machines on the market.

R&J Machinery is proud to be the Main UK Agent for Altendorf

R&J Machinery has a long relationship with Altendorf dating back to 1994, and we are proud to be the Main UK Agent and Sole UK Importer for their machines and spare parts. We are one of the top-tier suppliers of Altendorf saws across all of Europe, and our team of service and repair engineers travels to Altendorf in Germany annually for training on the latest machinery developments.

You can be sure that our team are fully qualified to offer you guidance on the ideal Altendorf table saw for you, and are fully qualified to service and maintain your existing machines to the highest standard. We look forward to talking to you soon about all things Altendorf!

For sales, servicing, parts, advice and support, please call our office team on 01455 840224.