Barbaric LCV Feeding System

The price for this product is on application only. Please contact us to discuss the options available to you.

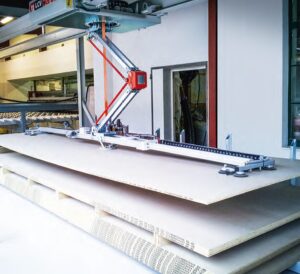

About the Barbaric LCV Feeding System

A Barbaric LCV Feeding System allows an easy and fast feeding of your manufacturing machine. In this area Barbaric can offer custom made systems built with simple yet high quality components. Benefits are low space requirement and the physical relief of production workers. An investment with tremendous value for craft and industry production.

All of the essential functions of the panel storage system CSF were retained at the feeding system LCV. By concentrating on essential functions the system can convince with simplicity and reliability.

All functions are integrated to save space: Lifting Motor, Horizontal Motor, Rotation Device (optional), Switch Cabinet.

Barbaric LCV Feeding System Features

-

Optimized material flow

-

Gentle manipulation, no damaging of the panels during transport

-

Optimization of space

-

Reduced personnel expenses

-

Simplification and alleviation of production processes

-

Payback periods below one year possible

-

Fully automated panel handling

-

Visualization in 2D and 3D system

-

Simple and intuitive user interface

-

Fully automated standardized hardware interfaces for different saw manufacturers

-

Automated panel feeding

Barbaric LCV Feeding System Options

-

Three axis system (XYZ)

-

Panel length and width longer on request

-

Stacking height up to 2,500 mm

Barbaric LCV Feeding System Specification

| Plant Size: System Design | Two axis system (XZ) |

|---|---|

| Plant Size: Length | Up to 50mm |

| Movement Speeds: X-Axis | 80 m/min |

| Movement Speeds: Z-Axis | 25 m/min |

| Panel Sizes: Length | 2000 mm - 4200 mm |

| Panel Sizes: Width | 600 mm - 2100 mm |

| Panel Sizes: Thickness | from 8 mm |

| Panel Weight | 200 Kg |

| Stack Height | 1800 mm |

| Stack Distance | 150 mm |

| Lifting Hole | 2000 mm x 600 mm |