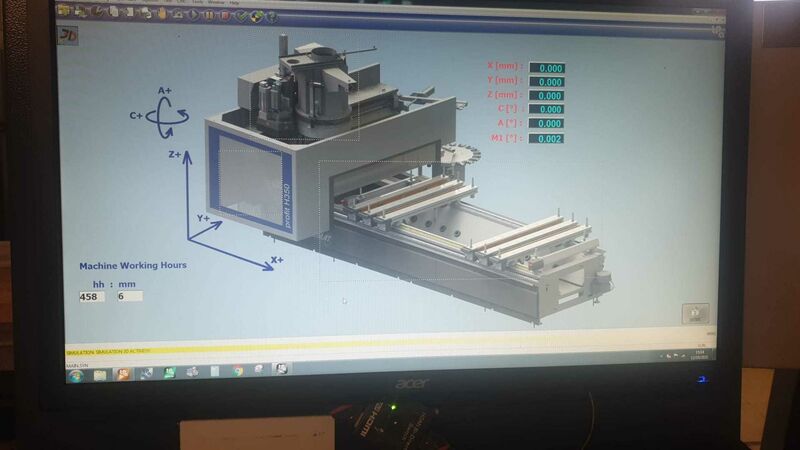

Used Felder Profit H350 5-Axis CNC router

Profit H350 16.30:

CNC machining centre with gantry design (without tools) with digital drive (driven from both sides).

The machine chassis of the Profit H350 16.30 is made from thick walled electrically welded shaped tubes. The steel ribbing inside the chassis ensures a high level of stabiliTY

Automatic central lubrication system:

The lubrication is applied as and when required to the X, Y and Z axes runner blocks as well as the ball screws in Y and Z. The lubrication process is automatically carried out after a specified time.

X-axis guiding system:

The gantry moves along the X-axis on a rail with angled, cambered teeth. - This guarantees maximum precision.

The reduction gears ensure maximum processing quality and repeatability. Encapsulated ball screws running along hardened and milled linear guides carry out the positioning.

Y-axis guiding system:

Positioning is carried out using encapsulated ball screws, running along hardened and milled linear guides. The Y axis is positioned using a milled ball screw.

Guiding system Z-axis:

Positioning is carried out using encapsulated ball screws, running along hardened and milled linear guides. The Z axis is positioned using a milled ball screw.

Working field H350 16.30:

Travel distance of the axis:

X= 4000 mm

Y= 1970 mm

Z= 455 mm

Working area:

X= 3000 mm

Y= 1550 mm

Z= 250 mm passage height from the level of the consoles depending on the clamping system, see layout

High performance PC

24" LED colour display screen

Keyboard, mouse and mouse pad- 1 USB Port

Hand held terminal to control the axis speed including emergency stop switch:

Performance specifications of the machine software Woodflash:

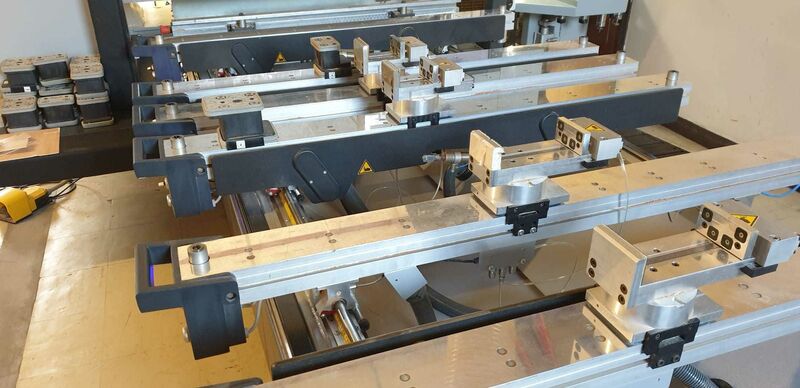

6 consoles:

with front and rear rows of fences Hose-free vacuum dual-circuit system with a vacuum pod height of 100 mm. Pneumatic adjustment of the workpiece supports running on hardened and ground round guiding bars. One front and rear, program controlled pneumatic cylinder on each of the supports. 4 positionable lateral stops in the Y direction. 4 loading supports make the loading or removing of larger or heavier workpieces much easier. The max. load capacity of each support is 20 kg - position in accordance with the machine layout.

Vacuum system 90m³/h

1 vacuum pump with a total vacuum capacity of 90 m³/h / 50 Hz

108 m³/h / 60 Hz

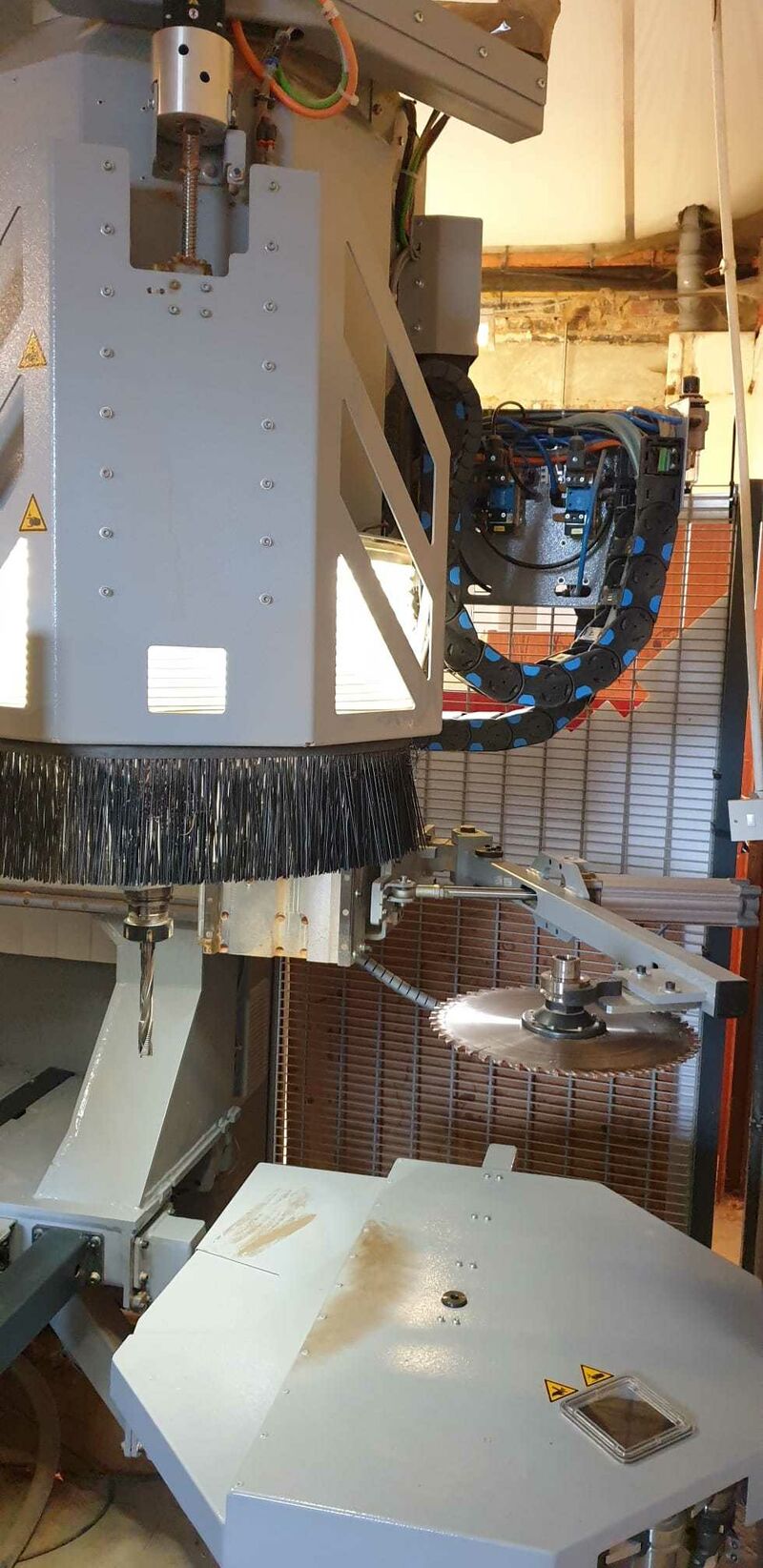

12 kW (S6) HSK F63:

24,000 rpm cardanic 5 axes electrical spindle, ceramic bearings including liquid cooling with a variable height adjustable extraction hood - electromotive control

Power requirement: 12 KW ( S6 )

Full power capacity at approx. 12,000rpm Rotating speed: 1000 - 24000 rpm

Drive: 3-phase high-frequency motor, controlled by inverter controlled rotation: right/left,

2 controlled compressed air connections, interface for units,

Tool weight (rotating): 6kg

max. saw blade diameter Ø 350, Cooling of the spindle: Liquid cooling Variably positionable extraction hood

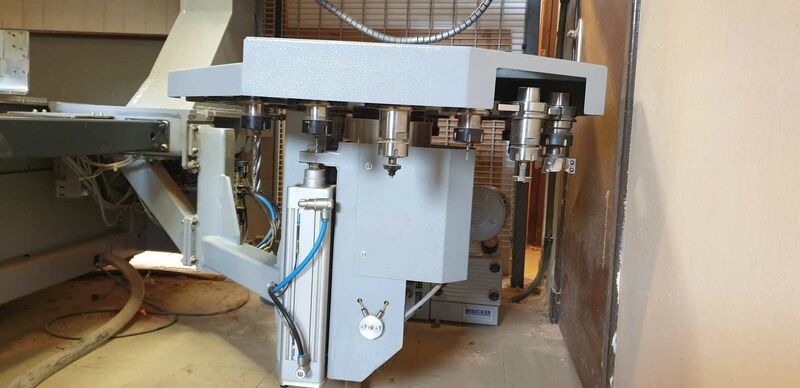

12 position linear tool changer to the left of the machine chassis including one pick up place for aggregates:

The 12 position linear tool changer ensures quick changeover times and offers sufficient space for milling tools.

One aggregate position

(See layout for configuration options) Max. tooling diameter 250 mm

Max. tooling length 240 mm

Safety system with a light barrier at the front side (a working area with a foot pedal).

Safety devices conforming to CE regulations

- Safety system with light barrier at the front (as standard)

Emergency stop switch

Safety fence on the left hand side of the machine

Secured door

Control sensors for the vacuum and compressed air

Number @453 - 1 Piece

Main spindle 12.0 kW (S6) spindle cooling: liquid-cooled

Number 902 - 1 Piece Machine language English

Number C12 - 1 Piece

USV interruption free power supply

Number C15 - 1 Piece

Closed cable draw in X and Y axis

This ensures that all cables, pipes and hoses contained in the cable cover are protected from damage.

Number C41 - 1 Piece

Safety system with bumpers including pendulum operation instead of a light barrier (!C21 /

!C40 / !C42)

Pendulum operation with two foot pedals.Reduced travel speed

Number C98 - 1 Piece

Optical status indicator of the machine

The 5-colour optical status indicatorof the machine shows the operatorduring the operation at a glancethe respective status:|green: in process|blue: waiting for operator's action|white: neutral|orange: warning|red: emergency

Number C99 - 1 Piece Blue LED strip lights (#C98)

Integrated into the front panel of the chassis.

Number C49 - 1 Piece

Controlled compressed air supply for frame clamps, 6 consoles (#C135) (!C21)

All usable compressed air frame clamps situated in the working area can be simultaneously opened and closed using the foot pedal. The vacuum required to keep the frame clamps in place remains. 3 compressed air supply connections per console.

Number C51 - 1 Piece

Activation of compressed air and vacuum for 6 consoles (#C46 / #C49 / #C135

This enables the separate manual movement of the vacuum pods/frame clamps on individual consoles, or the removal of offcuts, whilst the workpiece remains held or clamped in position.

Number C70 - 1 PiecE

2 continuous lineal fences in Y direction (!C21)

Mounted to the fence cylinders on the left and right edge of the working field

Number C189 - 1 Piece

Without drilling head, with electro-pneumatic and mechanical preparations for drilling head (!C190 / !C191) The drilling head can also be retrofitted with relatively little effort at the customers.

Number C91 - 1 Piece Additional locking of the C/A-axis

Includes the mechanical clamping of the C and A axis which reduces the strain on the motor and increases the usable service life.

Number C19 - 1 Piece

Safety fence on the right hand side of the machine

Number C88 - 1 Piece

Automatic tool length measurement system and 10 position linear tool changer on the left hand side of the machine chassis including pick up place for aggregates (!C86 / !C87)

The 10 position linear tool changer ensures quick changeover times and offers sufficient space for milling tools as well as an automatic tooling length measuring system.Automatic transferring of the length into the database.One aggregate position(See layout for configuration options)Max. tooling diameter 250 mmMax. tooling length 240 mm

Number C197 - 1 Piece

Pick up place for saw blade travelling in the X direction (!C82)

Tool position for a saw blade, mounted to the gantry.Maximum saw blade diameter is 350 mm. This ensures that no other tool positions need to be blocked in the tool changers, because of the large diameter of the blade.

Number C196 - 1 Piece

18 position rotary tool changer travelling in the X direction (!C84/!C85/!C195/!C196)

The rotation of the tool changer gives the machine access to up to 18 tooling positions or aggregates.The tool changer is mounted to the gantry.(See layout for configuration options)Maximum tool diameter 250 mmMaximum tool length 280 mm

Number C105 - 1 Piece

Real time video monitoring of the main spindle on an external screen whilst processing

Real time video control of theelectrospindle on a separate screen duringthe work processing. SDI cable andconverter for HDMI connection are included.The monitor to display the images it notincluded in the delivery. Electricalconnection of the HDMI converster must beorganises by the customer. From Woodflash4.2

Number C29 - 1 Piece

Mobile control terminal instead of a fixed control terminal (!C21 / !C28) (#C42)

Equipped with:- High performance PC- 24" LED colour display screen- Keyboard, mouse and mouse pad- 1 USB Port

Number C100 - 8 Piece Vacuum Pod 140 x 115 x 100 mm

Number C101 - 4 Piece

Vacuum Pod 125 x 75 x 100 mm in X

Hose-free dual circuit vacuum pod system. The replacable rubber covers guarantee an optimal grip of many different materials and can be used in a wide variety of machine operations.

Saw blade tool holder for H350

HSK 63-F D=110 mm, AL=65 mm, GL=97 mm, 8 NLA - Ø6,0 / TK90

including locking screws

1 ST

300-04-0150

Cutting saw blade (solid wood) for

saw blade holder 300-04-0767 350 x 4.4/3.2 x 30 Z= 48 WZ 8 NLA - Ø6.6 / TK90

4 ST

301-132

Horizontal frame clamps for Schmalz consoles with a clamping range from 0mm - 140mm. Height of the clamping device to the support surface 100mm. It can be used in the X and in the Y direction.

(Settings for the clamping range and the tilt are carried out manually).

Including 2 reference tabs and 2 reference plates