Rehnen Profile Shaping and Sanding Machine KBA

About the Rehnen Profile Shaping and Sanding Machine KBA

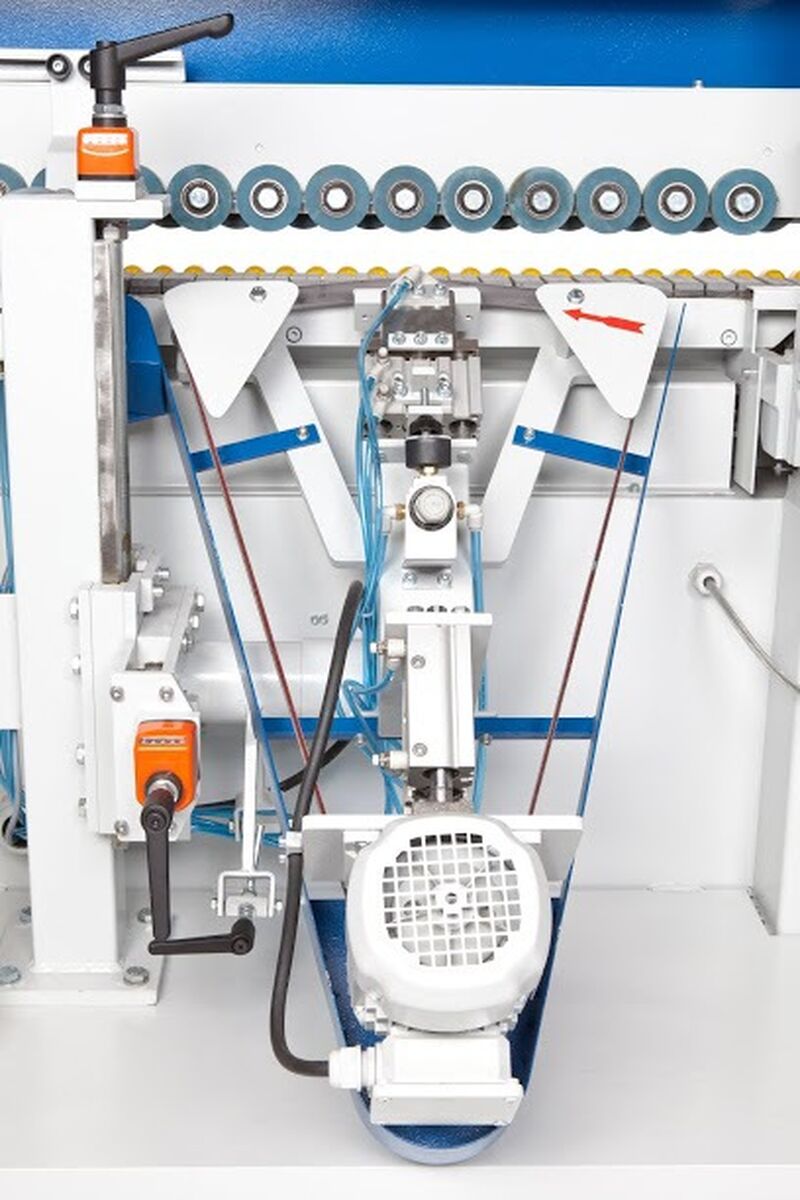

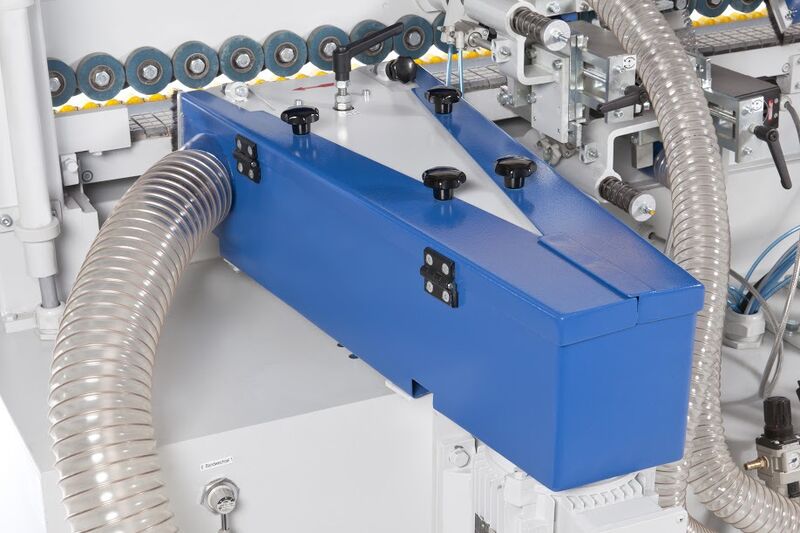

To make the process of edge-finishing solid wood, MDF and other board materials even more cost-effective and effective, the profile shaping and sanding machine from Rehnen has been further refined. Thanks to its modular construction, the KBA can be equipped with differing edge sanding units, milling units, profile sanding units and brush units. This means that different tools can be fitted to the finishing unit which, in turn, reduces machine set-up times.

The feed unit for the KBA takes the form of a chain plate feeder with a downholder bar that conveys workpieces firmly and securely past the finishing units.

Workpieces with a height of up to 80 mm and a length of 50 mm can be finished. The upper finishing units for profile milling and sanding travel along together in parallel and at the same height depending on the material thickness setting.

Rehnen Profile Shaping and Sanding Machine KBA Features

Rehnen Profile Shaping and Sanding Machine KBA Specification

| Total Motor Power | 6 kW |

|---|---|

| Motor Power of the Edge Sanding Unit | 3 kW |

| Sanding Belt Dimensions (edge) | 150mm x 2000mm |

| Continuously variable pneumatic oscillator, adjustable | 30-130mm |

| Motor Power of the Milling Unit | 0.55 or 1.1Kw |

| Motor power of the Profile Sanding Unit | 0.37kW |

| Sanding Belt Dimensions (profile) | 30mm x 1960mm |

| Machine Size | 1000mm x 3600mm |

| Feed Speed | 2-10 m/min |

| Material Thickness | 10-60mm or 20-90mm |

| Min. Material Length | 200mm |

| Min. Material Width | 40mm (during transport) |

| Weight | Approx 900Kg |

| Extractor Diameter | 1 x 160mm |

| Sound Power Level (DIN EN ISO 7346) - Idling | 86 dB(A) |

| Sound Power Level (DIN EN ISO 7346) - Finishing | 87 dB(A) |

| Noise Emitted at Work Station - Idling | 76 dB(A) |

| Noise Emitted at Work Station - Finishing | 77 dB(A) |

| Measurement uncertainty allowance K | 4 dB(A) |