Pre-owned Tigerstop fully automatic cross cut saw for angled and straight cuts - YEAR 2015

ITEM 1: Tiger UKA 600 Cross cut installation consisting of :

1 Tiger Stop 7.5 Automatic Stop and pusher

Total length : 7.95 meter

Working length : 7.35 meter

Net working length (automatic saw) : 6 meter

Voltage : 220 Volt 50 Hz

Motor power : 0,45 Kw

Feed speed : maximum 40 m/min

(Depends on load)

Précision : +/- 0,4 mm as pusher.

Infeed-table for TigerStop 6.8

Total length : 7.4 meters

Table width : 325 mm

1 Up-stroke angle cross- cutting saw model UKA 600

with pneumatic stroke and clamping device

Saw unit mounted on rotating table of diameter : 980 mm

Saw blade diameter : 600 mm

Cutting capacity : 165 x 240 mm 90 degrees

Maximum cutting height : 165 mm at the Fence and 175 mm Diameter

(at 90 degrees) for round material

Cutting angles : 30 – 90 – 30 degrees

45 – 90 – 45 degrees with automatic function

Motor power : 5.5 Kw

Voltage : 400 Volt 50 Hz

Working height : 920 mm

The machine is operated by push button for semi-automatic use or fully automatic for 90 degree angles controlled by the TigerStop. The rotation table is controlled by a Tigerstop Servo drive TigerDrive

1 Outfeed / infeed table with side fence

Length : 3.7 meter

Width : 325 mm

PC control with Beamworks programme, Computer with Touch Panel and computer cabinet

Cut list download possibilities for csv file.

Extension with 6 strand flipper-loading device

For automatic loading of material with length from 500 - 6000 mm. Shorter piece can be put directly on the infeed table

Loader consisting of :

6 flipper beams with tables including the 2 aluminium profiles 80 x 40 mm per beam, the flippers, the connecting tube, 1 pneumatic cylinder with 24 volt valve. The net loading length is approximately 1.38 meter.

1 extra support strand without flippers on the outside of loader

2 extra cylinder kit for loading device

Complete electric control cabinet with PLC , Power supply,

Emergency stop safety relais, complete wiring etc

(Including extra electric wiring for safety fence door)

Label printer Package for Beamworks

Safety fence at the back of the machine infeed side only Including entry door with safety lock and extra guarding at the front to prevent entry between the Loading strands.

Product length measuring with sensor inside the safety hood Controlled from the Tigerstop controller.

The length measuring and downloading with Tigerlinks works only on 90 degree cuts.

Tigerlink Download software for downloading csv file (cut list ).

TigerStop Servicing

Woodworking machines are only as good as their preparation. Our in-house team of trained engineers are on-hand to visit your workshop and provide you with scheduled TigerStop servicing, ensuring that your machines are optimised for maximum performance and continue to meet safety standards.

TigerStop Spares

As TigerStop's Main UK Agent, we are the supplier of choice to get your TigerStop spares to you in the quickest time at the best price. We can even fit them for you too should you need further assistance. To view and order items from our full range of spare parts and accessories please follow the link below.

TigerStop... Fast and accurate... every time

TigerStop was founded in a garage in 1994 by an ambitious husband and wife duo who wanted to help manufacturers like themselves reduce waste, measure material more accurately, and ultimately produce higher quality goods more efficiently.

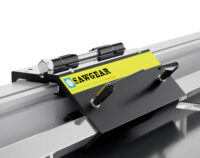

TigerStop has since become a global leader in automated stop/gauge and pusher systems under the TigerStop and SawGear brand names. Headquartered in Washington State, TigerStop is a U.S. manufacturer with a second manufacturing and distribution facility in Europe, a distribution network spanning six continents, and product support in five languages.

R&J Machinery is proud to be the UK Agent for TigerStop

R&J Machinery has a long relationship with TigerStop dating back over 20 years, and we are proud to be the Main UK Agent and Sole UK Importer for their machines and spares. We are one of the top-tier suppliers of TigerStop products across all of Europe, and our team of service and repair engineers travels to TigerStop EU in Holland annually for training on the latest machinery developments.

You can be sure that our team are fully qualified to offer you guidance on the ideal TigerStop setup for your workshop, and are fully qualified to service and maintain your existing machines to the highest standard. We look forward to talking to you soon about all things TigerStop!

For sales, servicing, parts, advice and support, please call our office team on 01455 840224.

Request TigerStop Servicing Information

R&J Machinery's in-house team of trained engineers are on-hand to visit your workshop and provide you with scheduled TigerStop servicing. To request more information about the servicing packages we offer, please speak to our knowledgeable team on 01455 840224 or complete this enquiry form.