Reinbold AZR 800 Special Shredder

Our Price

£POA

Availability

Available Now

The price for this product is on application only. Please contact us to discuss the options available to you.

For sales and advice call today!

01455 840224

About the Reinbold AZR 800 Special Shredder

The AZR 800 Special Shredder series provides a compact design combined with great power. These machines are best suitable for use in small or medium-sized companies which attach great importance to an optimum cost-benefit ratio. Further features include: robust design, high throughput rates, excellent reliability, operator-friendly, easy maintenance, low operating costs, wide range of applications.

Reinbold AZR 800 Special Shredder Features

-

Perforation size: The standard size is 15/20 mm

-

Throughput rate: This parameter depends on the type of material being processed (long, short, wet, dry, etc.) as well as on the size of the screen perforation. A machine usually processes between two and four hopper fillings per hour.

-

Removal of chips: For this purpose you can use a suction plant, a conveyor screw or a conveyor belt. The minimum air speed for suction plants is 28 m/s

-

The rotor shaft is made of solid steel. Adjustable cutting gap between rotor and counterknife (optional)

-

Hydraulic feed to ensure constant material feed to the rotor

-

Hydraulic cylinders suspended by cardanic joints prevent shortening of piston cup service life

-

Range of different screen mesh sizes for required chip size depending on material and task

-

Security package with gear end limit switch and reverse counter

Reinbold AZR 800 Special Shredder Options

-

Perforation size: (mm): 10/12, 12/15, 20/25, 25/30, 35/40 Special sizes on request

-

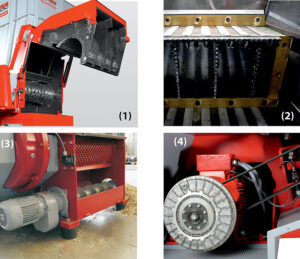

Chip Removal:Options: (1) = Pivoting filter basket (2) = 4-sided segment bottom tine plate and spike bar (3) = Discharge by auger (4) = Turbo clutch from 30 kW

-

18.5kW Motor

Reinbold AZR 800 Special Shredder Specification

| Hopper opening | 800 mm x 1,000 mm |

|---|---|

| Hopper volume | 0.9 m³ |

| Throughput rate | Depends on the type of material and screen used |

| Rotor-Ø | 252 mm |

| Rotor speed | 90 rpm approx. |

| Power consumption | 22 kW |

| Tools | 40 Pcs |

| Screen perforation | 10 - 40 mm |

| Suction port-Ø | 200 mm |

| Air speed | 28 m/sec |

| Weight | 1500 kg |