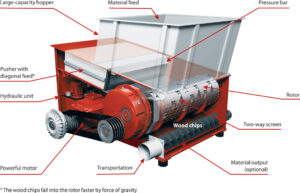

Reinbold Single Shaft Shredder AZR 1300 S

The price for this product is on application only. Please contact us to discuss the options available to you.

About the Reinbold AZR 1300 S Single Shaft Shredder

The Reinbold AZR 1300 S is extremely powerful. The solid construction allows for the efficient and economic shredding of bulky and large materials.

The functionality of the Single Shaft Shredders:- large-capacity hopper

- quiet operating slider for constant material feeding

- sturdy and robust hydraulic unit

- different types of rotors for various types of recyclable material

- various perforated screens for different chip sizes

- different types of collection units to choose from

- powerful motors

Recyclable material is involved in all production processes carried out by the industries. Usually, these materials can be returned to the production process.

Having many years of experience in the field of shredding recyclable material, Reinbold Waste disposal technology is able to offer you an integrated solution for use in the production process as well as in the production workflow with its shredders of the AZR 1000. There is a choice of different machine types, sizes and size reduction techniques. This allows us to create a perfect solution to suit your personal production profile and requirements

For further information regarding this machine please contact the sales team on 01455 840224.

Reinbold Single Shaft Shredder AZR 1300 S Features

-

Hydraulic cylinders suspended by cardanic joints are used to prevent the service life of piston cups being shortened

-

Hydraulic feed to ensure constant material feed to the rotor

-

All machines can be operated using a programmable control system (e.g. flow control, feed control, automatic switching-off if empty hopper is detected, etc.)

-

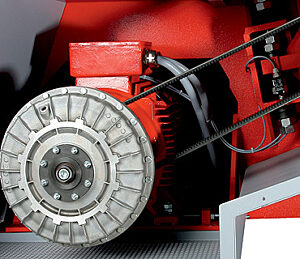

Powerful drives from 9.2 to 150 kW depending on the performance requirements. A high degree of efficiency due to turbo coupling (from 22 kW)

-

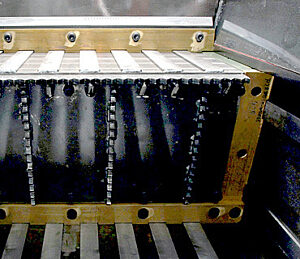

Perforation size: The standard size is 15/20 mm

-

Throughput rate: This parameter depends on the type of material being processed (long, short, wet, dry, etc.) as well as on the size of the screen perforation. A machine usually processes between two and four hopper fillings per hour

-

Removal of chips: For this purpose you can use a suction plant, a conveyor screw or a conveyor belt. The minimum air speed for suction plants is 28 m/s

Reinbold Single Shaft Shredder AZR 1300 S Options

-

Perforation size: (mm): 10/12, 12/15, 20/25, 25/30, 35/40 Special sizes on request

-

Removal of chips: Options: = Movable screen cage = 4-sided segmented floor, serrated plate and serrated rail = Delivery by worm srew = Turbo clutch from 30 kW

Reinbold Single Shaft Shredder AZR 1300 S Specification

| Hopper opening | 1,300 mm x 1,200 mm |

|---|---|

| Hopper volume | 1.65 m³ |

| Throughput rate | Depends on the type of material and screen used |

| Rotor-Ø | 354 mm |

| Rotor speed | 90 rpm approx. |

| Power consumption | 37 / 45 / 55 kW |

| Tools V5 + V7 | 33/66/99 pcs |

| Screen perforation | 10-50 mm |

| Suction port-Ø | 250 mm |

| Air speed | 28 m/sec |

| Weight | 3,800 kg |