Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

Select and purchase TigerStop spares parts from R&J Machinery, the official UK stockist.

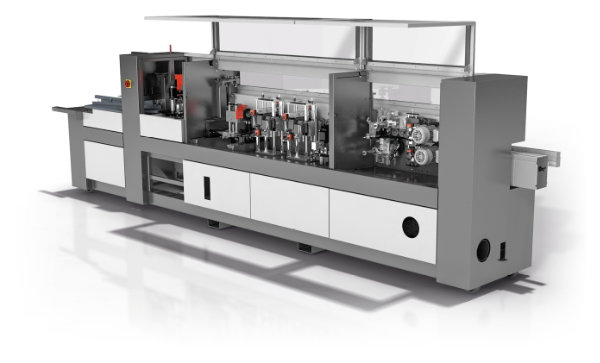

Select and purchase Hebrock edgebander spares parts from R&J Machinery. We are the official UK stockist.