Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

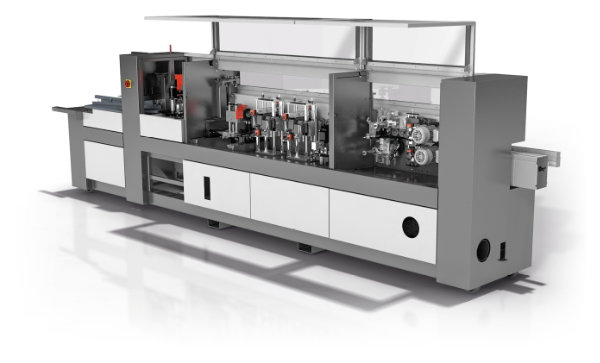

SCM K360 Edgebander

Automatic single-sided edge bander for the edge gluing with hot melt glue on straight panels, on the four panel sides, finishing and rounding-off of the panel corners

Main frame made of bended and welded steel plates to ensure a high rigidity structure

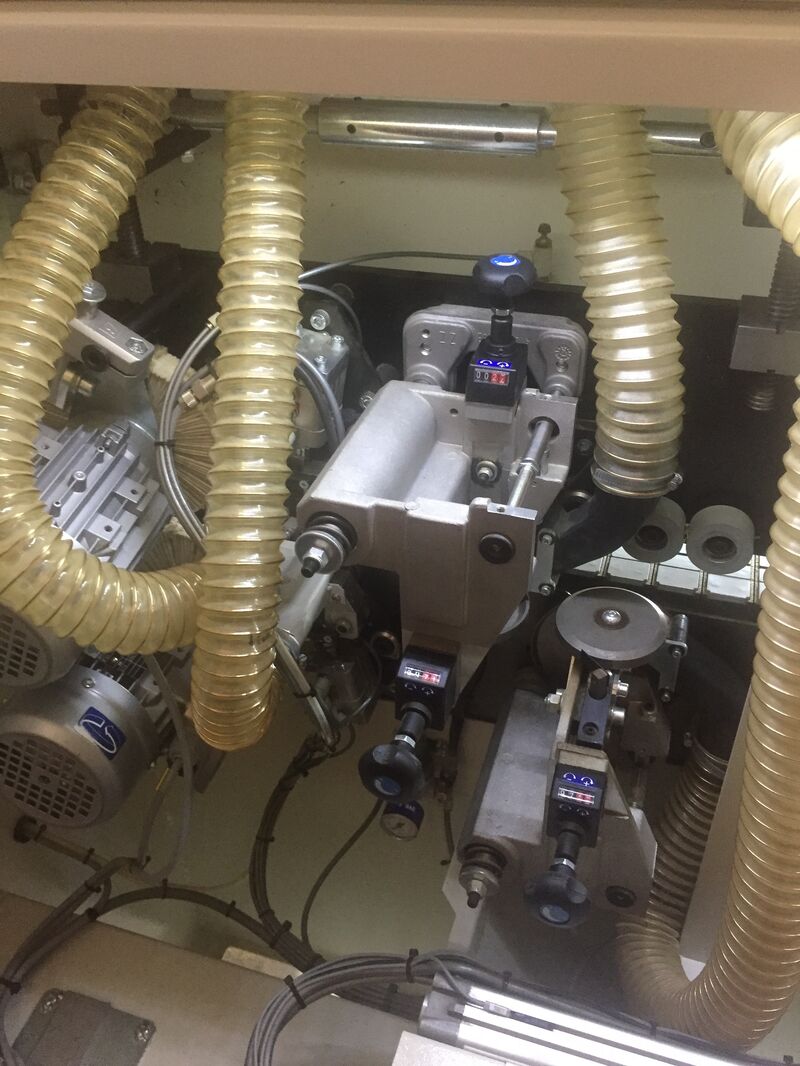

Top steel presser, complete with two rows of rubber coated wheels mounted on bearings and enclosure that covers the wheels.

Manual adjustment of presser at machine infeed with positioning numerical readout

Top operating groups fixed to the presser or mechanically connected on to it to allow the automatic positioning according to the panel thickness. Lower groups fixed to the horizontal beam for a precise reference with respect ot the panel.

All frequency motors equipped with inverter.

Safety enclosure on the entire length of the machine with poli-carbonate windows for the groups visualisation during machining.

Exhaust outlets for the operating groups positioned on the top side of the safety enclosure

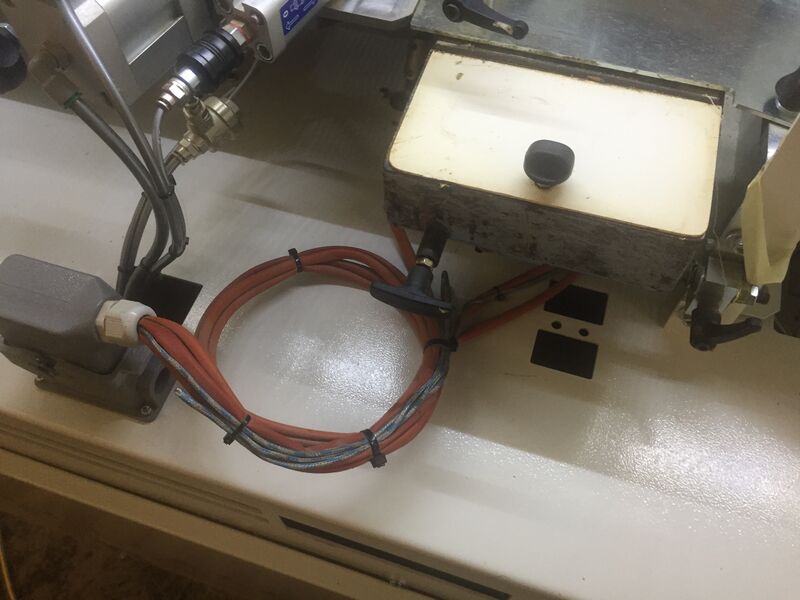

Mobile control panel at machine infeed for an easy use from the operator's working position

Electrical cabinet positioned inside the main frame with door that allow an easy access in case of any maintenance operations. The cabinet is in conformity with the current safety regulations

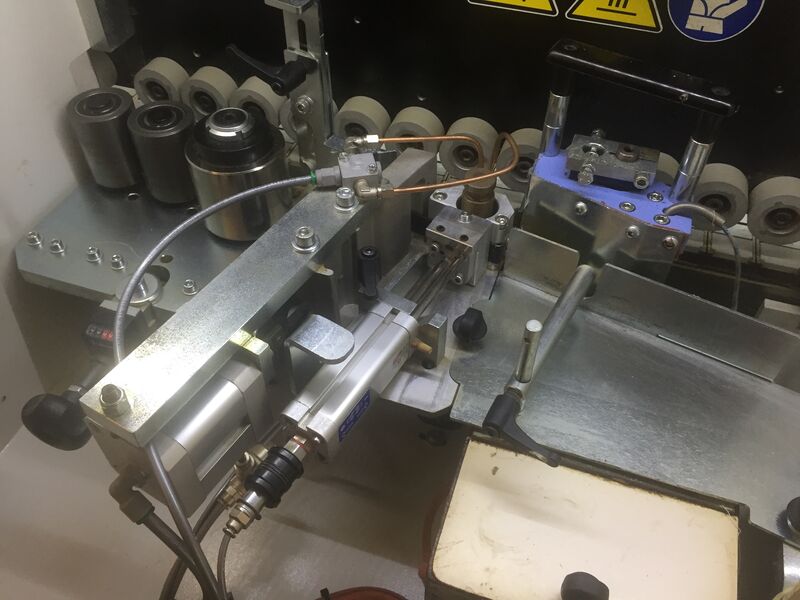

It trims the panel edge obtaining a perfect uniform surface for the glue application and a perfect jointing line with the edge.

two high frequency motors. Motor operation is timed to prevent chipping on the panel

exhaust hoods

timed air blower for the cleaning of the machined panel surface

panel edge trimming with a variable removal, adjusting the infeed fence position by means of knob and numerical readout

height adjustment of the tools to vary the cutting point

complete with diamond cutters (H=49mm – D=100mm – Z=2+2). (45mm maximum panel thickness to be processed)

Key Features

SCM K360 Edgebander Specification

| Distance between two successive panels | 600 mm |

|---|