Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

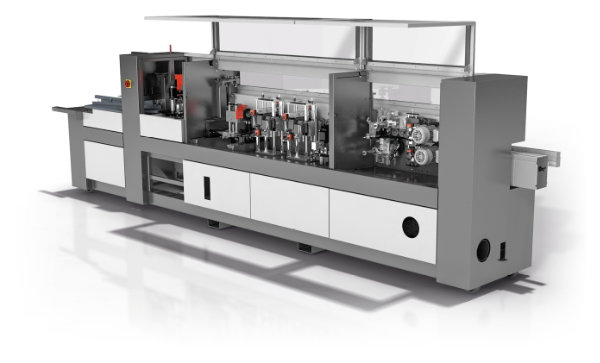

Used Biesse Akron 1440 Edgebander

About the Used Biesse Akron 1440 Edgebander

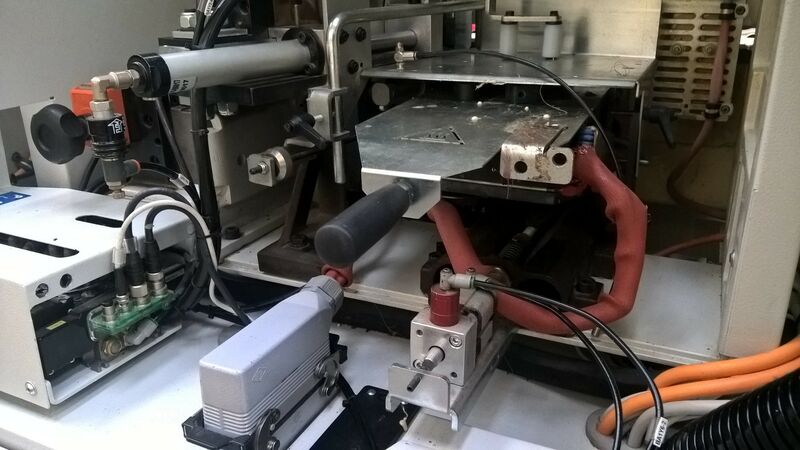

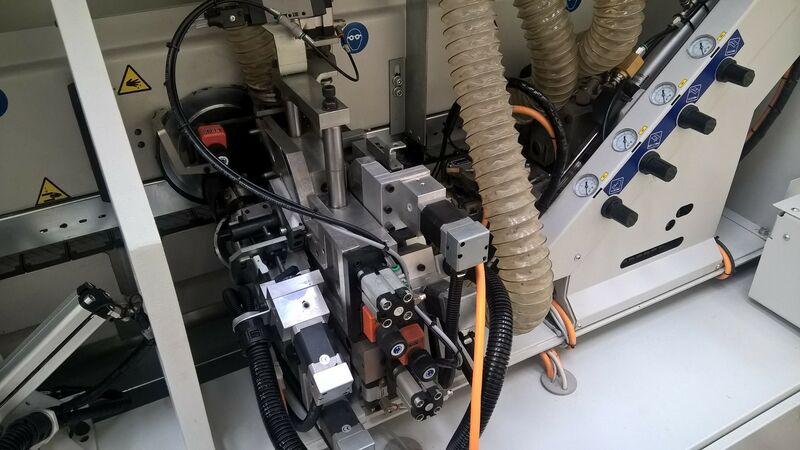

Excellent chance to buy a Biesse Akron 1440- A Edgebander with PUR glue station. Machine benefits from Pre-milling, Tilting top and bottom trimming unit with axis control, Profile Edge scraper, flat / glue scraper, Brushing unit, Anti-adhesive unit, Diamond coated cutters 65mm, Pro glue kit, Infrared heating lamp, Corner Rounding, Machine equipped with R=2mm tooling, and flat knives for solid wood.

Machine was delivered in December 2014, and is in excellent condition.

Used Biesse Akron 1440 Edgebander Features

Used Biesse Akron 1440 Edgebander Specification

| Panel height | 10-60 mm |

|---|---|

| Panel height with corner rounding unit | 10-35/60 mm |

| Height of edgebanding material | 14-64 mm |

| Thickness of edgebanding material in rolls | 0.4-3 mm |

| Thickness of edgebanding in strips | 0.4-10 mm |

| Panel protrusion from track | 25 mm |

| Min panel length | 140 mm |

| Min panel width (with length 140mm) | 85 mm |

| Min panel width (with length 250mm) | 50 mm |

| Track feed speed | 12 m/min |

| Dust extraction system for pre-milling unit | 1 hood Ø 100mm |

| Dust extraction for PU glue fume removal | 1 hood Ø 100mm |

| Dust extraction system for end trimming unit | 1 hood Ø 100mm |

| Dust extraction system for trimming unit | 1 hood Ø 100mm |

| Dust extraction system for corner rounding unit | 1 hood Ø 100mm |

| Dust extraction system for edge scraper | 1 hood Ø 100mm |

| Dust extraction system for glue scraper | 1 hood Ø 100mm |

| Dust extraction for spindle moulder | 1 hood Ø 100mm |

| Pneumatic connection | 7 bar |

| Working voltage | 400V / 50Hz three phase and neutral |

| Control voltage | 24 V-CC |

| Static frequency inverter | 200 Hz |

| Glue pot capacity | 2 Kg (approx) |

| Glue pot heating time at half load | 10 mins (approx) |