Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

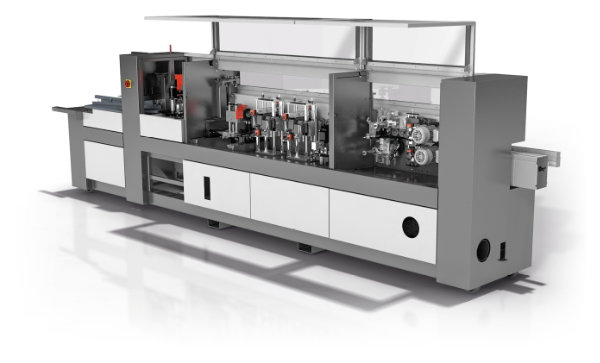

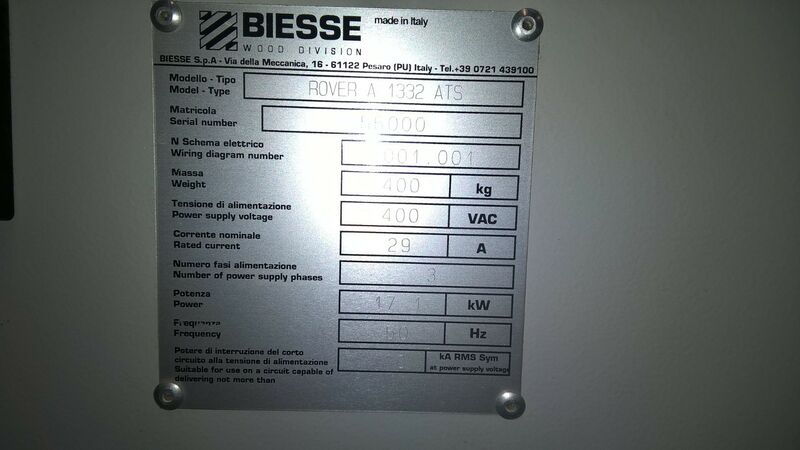

Used Biesse Rover A 1332 ATS

About the Used Biesse Rover A 1332 ATS

Excellent chance to buy a Biesse Rover A, manufactured in 2013, with little use...

Machine is available from March 2017.

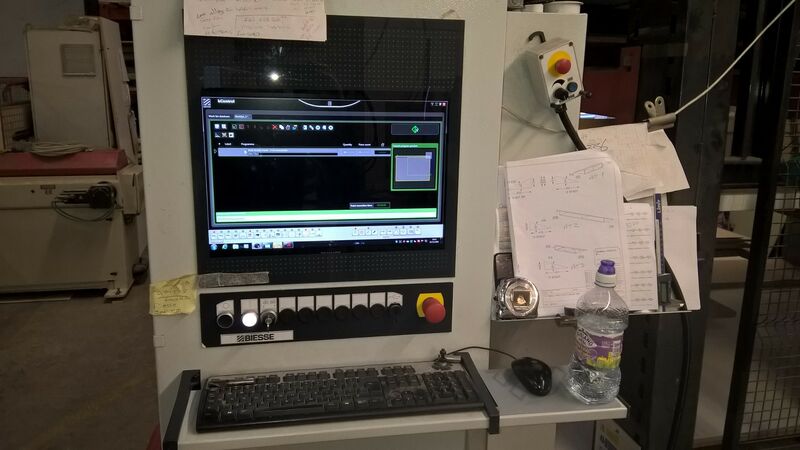

The Biesse Rover A ATS CNC machines are designed with Flexibility and strength, typically of the top level of CNC Machines offered from Biesse. The machine has a double Z axis, which enable the machine to process large solid wood components, with large tools and aggregates... with 'C axis' and tool changer.