Select and purchase Altendorf spares parts from R&J Machinery. We are the home of Altendorf UK, and offer the widest range at the best prices.

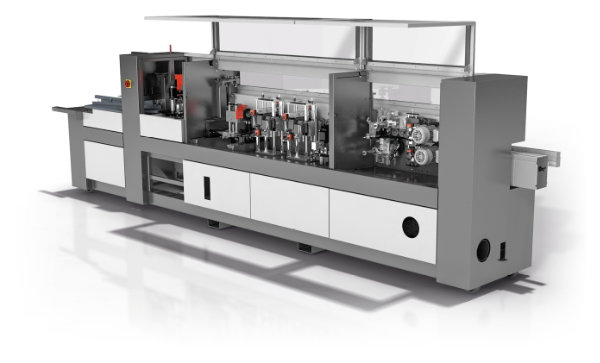

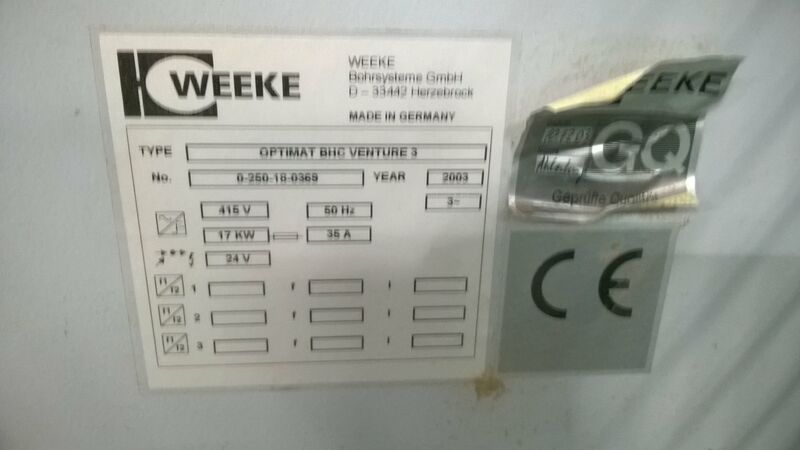

Used Weeke Venture 3

Weeke Venture 3 in very good condition with 4th Axis from year 2003, machine has been very well looked after, and is only available due to the previous owners upgrade to a 5 axis Machine.

Machine has main Router, Vertical and Horizontal drills and saw. The machine is now in stock at R&J Machinery.

Please contact our sales team for more information or to view the machine.

BASIC MACHINE

- Basic machine frame and carriage in solid ribbed steel construction

- Carriage movable in X-direction

- Cross support movable in Y- and Z-direction

- Paint grey RDS 240 80 05

- Central extraction of the processing unit and separate dust connection for the dust extraction device

GUIDING SYSTEM AND DRIVE TECHNIQUE

- Axis adjustment (X-/Y-/Z-direction) via a compact linear guiding system, dust protected Rack gear in X-direction and ball bearing spindle in Y- and Z-direction

Travel range of the axes:

X = 3810 mm

Y = 1735 mm

Z = 220 mm

- Digital drive technique in X-Y- and

Z- direction. (Sercos)

Axis speeds:

X = 100 m/min

Y = 50 m/min

Z = 20 m/min

Consisting of:

- maintanance free AC servomotors with high resolution optical encoder and high system precision.

- digital drive control with higher reliability and faster cycle times (2 ms)

- digital control via lightwave conductor bus-system (SERCOSRING)

3. CONSOLE TABLE WITH LED- DISPLAY

Tubeless vacuum clamping system for clamping of coated and uncoated plate materials.

The positions of the workpiece consoles which are programmed in WoodWop can be displayed at the consoles by LED-display.

The individual positions are adjusted by measuring scales and indicators.

The workpieces consoles are guided on a dust protected, hardened and ground guiding system. For adjusting the workpiece consoles are unclamped pneumatically.

The vacuum cups are clamped by means of a vacuum.

Working field:

X = 3250 mm (Length)

Y = 1220 mm (Width)

Z = 125 mm (Thickness)

The max. workpiece thickness which can be processed depends on the length of the tool

Consisting of:

6 workpiece consoles which can be infinitely adjusted in X-direction, suitable for the tubeless positionable vacuum cups

6 LED displays for optical control of the console and vacuum cup positions.

6 measuring scales in X-direction (1 per console)

1 measuring scale in X-direction

Stop cylinders to position the workpieces to be processed. All stops are lowerable via program.

4 rear stops for workpieces with a width of more than 960 mm

6 front stops for narrow workpieces with a width of more than 960 mm

2 stops for lateral positioning of the workpieces in width for the right hand working field (manually adjustable)

2 stops for lateral positioning of the workpieces in width for the left hand working field (manually adjustable)

6 tilting stops which can be fitted manually, for surface material overhang

Note: for the front stop row

4 controlled workpiece feeding rails (synthetic material) for easy positioning of heavy workpieces. (fitted to the consoles 1, 3, 4 and 6)

1 vacuum connection for connection of selfmade templates to the right hand working field

1 liquid cooled low-maintenance vacuum pump with a capacity of 100 m/min.

1 Laser pin

Via a separate NC-program the exact vacuum cup positions are shown via a laser beam (cross hairs).

The laser is fitted to the processing support of the machine. The positions which were adjusted via LED display and scales can be controlled additionally in rapid traverse

During this operation the operator is not permitted to enter the safety area of the safety mats.

Router contour control:

The laser control for the router contour can be programmed in WoodWOP. The cross hair laser can therefor carry out the control of the vertical router contour (center point lane).

The complete contour is not displayed graphically instead the router contour is simulated.

Hand terminal

- With potentiometer and emergency stop switch to control the machine (e.g. for running of complex processing programs)

5. PROCESSING CONFIGURATIONS

V19,H4X/2Y,G1,F1-HSK-9KW,C-Axis,TC8 rear

V19 HIGH SPEED 7500 incl. quick change and spindle clamping.

Vertical drilling aggregate with manual quick changing system and steplessly programmable High Speed range.

Furthermore the vertical individually selectable spindles are equipped with forced spindle clamping to ensure the required drilling depth.

Working capacity: refer to separate layout

Pre-stroke

Z-direction: 60 mm

Drilling depth: max. 38 mm (up to 55 mm but witha special drill)

Rotation: right/left

RPM: 1500 - 7500 1/min, frequency controlled

Drive: 2,7 kW

Shaft diameter: d = 10 mm

Total drill length: 70 mm

Drill diameter: max. 35 mm

Spindle distance: 32 mm

Spindle type: individually selectable

Arrangement: 9 spindles X-direction (row holes)

8 spindles Y-direction (construction)

2 separate spindles.

H4X/2Y

Horizontal boring block with 4 spindles in X-direction which can be activated separately.

Two spindles each (pitch 32 mm) arranged right and left hand in X-direction.

Working capacity: refer to separate layout

Drilling depth: max. 38 mm

Drilling height in Z-direction: 38 mm from upper workpiece edge

Direction of rotation: right hand / left hand RPM: 1500 - 7500 1/min frequency-controlled

Shaft diameter: 10 mm

Total length of drill: 70 mm

Drill diameter: max. 20 mm

Type of spindle: individually selectable

Horizontal drill block with 2 individually

selectable spindles via program.

1 spindle each arranged at the front and rear in Y-direction.

Working capacity: refer to separate layout

Drilling depth: max. 38 mm

Drilling height in Z-direction: 38 mm from upper workpiece edge

Direction of rotation: left RPM: 1500 to 7500 1/min frequency-controlled

Shaft diameter: 10 mm

Total length of drill: 70 mm

Drill diameter: max. 20 mm

Type of spindle: individually selectable

GS1

Grooving saw in X-direction

Working capacity: refer to separate layout

Cutting depth: 10 mm

Cutting section: max. 50 mm2

Direction of rotation: right hand

Speed: 2000 to 6500 1/min frequency-controlled

Saw blade

inner bore: 30 mm

Tool diameter: 100 mm

Saw blade thickness: max. 5 mm

R1-HSK63-9 KW

Tool change routing spindle incl. liquid cooling system for the use of shaft tools which are automatically changed from a plate changing magazine.

Working capacity: refer to separate layout Tool holder: HSK cone

Tool changing automatic

Direction

of rotation: right hand / left hand Speed: stepless 1250 - 24000

1/min programmable

Drive: frequency controlled

AC-motor

Max. capacity at the tool: up to 7,5/9 kW in continuous and intermittent operation (S1/S6 - 50%)

Spindle

lubrication: permanently lubricated

Cooling: liquid cooling system

Bearing: hybrid bearing(ceramic) less friction, higher stiffness and max. operating life C-AXIS AGGREGATE INTERFACE To take the adapter aggregates. Incl. interface pneumatics and rotatable drive

(stepless C-axis with torque a. 3-pointsupport)

C-Axis range: 360 degrees

Torque: for 3 point-support

Gear: slanted toothed gear pinion

TC8 REAR

Automatic tool change magazine for 8 places (plate changer),set up in X-direction moving with the support.The change plate magazine is designed for the use of routing tools with HSK cone.

Arrangement: in X-direction moving along with the support

Magazine places: 8 tool places

Due to varying construction of different routers the numbers of tools which can be placed into the magazine can vary as well.

Tool weight: max. 5 kg incl. HSK holder

Tool diameter: max. 100 mm when equipping with 8 router tools

Possible tool diameter: max. 100 mm when fully equipped(8 router tools) max. 160 mm when using tools with small diameters or with empty places besides Adapteraggregates: max. 4 can be equipped

Tool change time: approx 12 - 18 sec. chip to chip

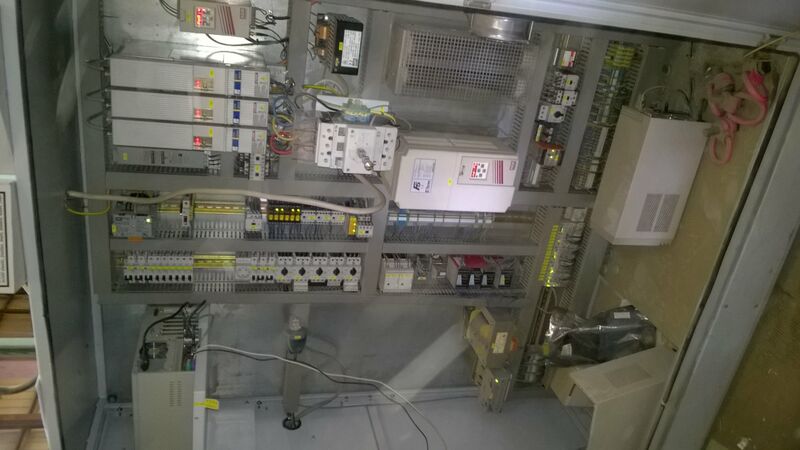

6. CNC Control and Software

The electrical switch cabinet with

integrated operating board is positioned

freely at the right hand machine side.

6.1 HARDWARE: POWERCONTROL SYSTEM

- CNC-Control incl. drive modules

- Intelligent control system, while the

CNC-Control steers the processes new data

can be independantly inserted at the PC

- PC (Personal Computer) for operator guiding

- Intel Pentium 4

- English operating system Windows XP embedded

- 15 inch TFT graphic monitor

- min. 256 MByte RAM

- min. 40 GByte HDD

(diverse partitions)

- 3 1/2 inc diskette drive

- Free port (EtherNet) is optionally onboard

Addtionaly PCI ports allow further

network cards

- Seriel interface for barcode, modem

oder ceiling laser

- Parallel interface for printer

- CD-ROM-drive for reading and writing of

CD`s (no dust protection guaranty)

6.2 SOFTWARE: POWERCONTROL SYSTEM

- WOODWOP

WOODWOP is a workshop orientated programming

system (WOP), which has been designed

especially according to the requirements of

a stationary technology in industry and

craft. Operator guiding for easy programming

processing programs. Due to a standardized

data format processing programs can be

interchanged between different machines

of the Homag group.

MACHINE DATA RECORDING (MDR)

The machine and service data record memorize

the number of workpieces, operation times,

idle times, breakdown times and production

times. When a pre-determined limit is

displayed an automatic maintenance request

is given.

PRODUCTION LIST

Within the production list the production

steps can be organized and recorded.

The lists are processed line by line or

on all places at the same time. Up to 10

variables for the use of variant programming

can be defined.

NC-SIMULATION AND TIME CALCULATION

A ''moving'' aggregate layout simulates the

processing steps in the determined order of

the NC-program.

Further parameters are possible:

- Time calculation approx. +/- 10%

- Positioning area

- Collision check

- Checking of the vacuum cup position

Simulates all 3-axis processings.Delivered

with copy protection (dongle).

7. SOFTWARE FOR EXTERNAL PC

- 3D WOOD DESIGN PACKAGE

The Wood Design Package is a modern 3D

construction program for the interactive

creation of carcase furniture and interior

elements.

- WOODWOP FOR PC

With this programming software processing

programs can be created on a PC externally,

e.g. in the engineering department.

8. PROVISION TELESERVICE, MODEM

Comprises the general provision of teleservice

capability of the machine incl.modem

and use of teleservice features within the

guarantee period. After the guarantee period

a corresponding teleservice contract must be

signed in order to use the teleservice.

9. CE-SECURTIY- AND SAFETY UNITS.

- Safety fences in the lateral and rear

areas.

- The saftey mats divided in 3 areas in front

of the machine for two-field operation.

While the machine operator sets up one work

field side the processing center can carry

out the processing on the opposite side.

10.USV INCLUDING VOLTAGE STABLIZER

Supplies the electronics as well as the

regulating circuit with electricity for

appr.3 minutes via the integrated batteries.

The interruption-free power supply also

serves as a voltage stabilzer for the

electronics as in case of overvoltage resp.

undervoltage the batteries are also in

operation.

11.WEEKE QUALITY PACKAGE

- The energy supply cable (cable tow)

in X-Y and Z-direction are supplied in

sealed execution.

- The energy supply cable incl. pneumatics

(cable tow for the workpiece supports) is

supplied in sealed execution.

- The linear guides in X-and Y-direction

are delivered with a protection cover(metal)

12 TOOLING START-UP KIT

- DRILLING

1 pc. cylinder head drill Z2+V2HM d = 15 mm

(30300-5-15070-L)

1 pc. cylinder head drill Z2+V2HM d = 35 mm

(30300-5-15070-R)

4 pcs. dowel hole drills HM d = 5 mm

(30540-5-05035-R)

5 pcs. dowel hole drills HM d = 5 mm

(30540-5-05035-L)

7 pcs. dowel hole drills HM d = 8 mm

(30540-5-08035-R)

7 pcs. dowel hole drills HM d = 8 mm

(30540-5-08035 L)

HSK- TOOL HOLDER

2 HSK tool holders

(1 x short version Sales No. 9501)

(1 x long version Sales No. 9502)

1 collet d=25mm

1 collet d=10mm

GROOVING SAW BLADE

Diameter 100 mm

1 flat tooth grooving d = 100 mm/W= 3,2 mm

d = 30 mm Z = 20

13. DOCUMENTATION

- Documentation in printed form and as

CD-ROM incl. spare-parts catalog and switch

plan

Number : 1603 1 x left

HSK63 DRILLING/ROUTING/SAWING, 2 SPINDLES

Drilling depth: max. approx. 50 mm

Tool holder: for collet ER 25

Tool diameter: max. 20 mm

Cutting depth: max. approx. 50 mm

Router receptacle: for collet ER 25

Saw blade diameter: 150 mm to 180 mm

Sawing depth: max. 40 mm

Saw blade thickness: max. 8 mm

Saw blade holder: 30 mm receptacle

drilling, 4 side drills

5,5 mm diameter,

partial circle 52 mm

diameter

Rotation: max. 15000 1/min

programmable

Indexing angle: 360 degrees

Aggregate holder: HSK F63 cone

Tools and collets are not included!

Note: The saw blade has to be unclamped during

boring or routing. For a saw blade diam.

of more than 150 mm the unit is automatically

placed into the tool changing

magazine.

For the BHC 2xx and 3xx the aggregate is placed

in the magazine after processing.

G.0004 Number : 6303 1 x left

BARCODE READER HAND SCANNER, CORDLESS

Reader: Datalogic DLL6010-R, internal decoder

no display

For reading of barcode information from

a label.

G.0007 Number : 6310 1 x left

BARCODE SOFTWARE (BARCODE CONTROL)

The barcode control is prepared for connection

to a barcode reader of Datalogic.

Software to read a barcode via the seria

interface. The software allows for the

following individual adaption of the barcode

information:

- program name

- place number

- modus for two places at the same time,

e.g. for alternating processing

left hand part

The barcode can additionally include up to

4 variables (5-digit, in 1/10 mm). When using

variables the new NC-program is automatically

generated after scanning through the production

list.

Further functions:

- Creating of production lists with help of the

barcode, additionally a rated value can be

passed on in the barcode.

- Connection of the barcode software to the

project manager (software interface to

branch packages - VKNR 6070). An imported

project which includes the barcode for this

part as an index can be processed with the

barcodes irrespective of the sequence in the

production list.

- support and vacuum cup positioning can be

displayed as a graphic or optional as a

laser projection.